Exploring The PLC configuration

Programmable Logic Control (PLC) is one of the most successful, efficient, and widely used industrial tools to monitor, control, and optimize process parameters. The importance of the PLC system comes from its advantages such as productivity increases, efficiency increases, high-quality production, and maximum safety enhancement. |

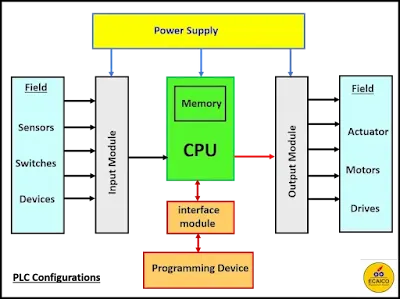

| PLC Configuration |

In the previous automation article, we discussed the definition, advantages, and applications that use the PLC. In this article, we will continue with the hardware and software components related to the PLC system as well as the programming concept of it. we also give a short review for each part of it to complete the haul story about the PLC system.

What are the hardware components of a PLC system?

The hardware of the programmable Logic Controller (PLC) is the physical components or devices designed to support the monitoring, controlling, and automating of any industrial processes. There are a standard component but the final setup is determined based on the type and function of each process. The following is the common standard configuration1- Power Supply (PS).

The power supply unit provides the PLC components like the CPU, input modules, output modules, communication modules, and the programming interface module with the necessary current and voltages for the system operation. the power supply module may contain batteries for emergency cases.

2- Central Processing Unit (CPU).

CPU is the main core processing unit of the PLC system same as the computer that is responsible for executing the control program designed for each application. It also processes the input/output signals, supporting and coordinating the communication between different PLC system modules.

3- Input Modules (I/P).

The input modules are the modules that are responsible for receiving the field signals from the sensors, switches, and instrumentations like temperature, pressure, and level. It converts it to a certain form of data (analog or digital) to be processed by the CPU. Input modules include digital, analog, and special types of modules that depend on the processes.

4- Output Modules (O/P).

According to the process program, the output modules are responsible for delivering the output signal calculated by the CPU in a certain form of data to the field drives, motors, actuators, or other devices.

5- Memory.

Similar to a computer, the PLC system includes different types of memory such as data memory which holds the temporary data used for calculations and processing, system memory which stores system parameters and configuration settings, and program memory which stores the programmed logic and instructions for controlling the system.

6- Programming Interface.

The programming interface is essential for the operation of PLC. it allows users to create, test, monitor, modify, edit, upload, and download programs from or to the PLC system.

7- Communication modules and Ports.

Communication modules are attached to the PLCs to enable data exchange with external devices, networks, and control systems while the ports allow remote monitoring, diagnosing, and programming. It also supports integration with other systems.

8- Human-machine Interface (HMI).

HMI is a screen or panel that allows operators to view real-time data, monitor faults and errors, control the equipment operation, and set all the system parameters. HMI can include buttons, charts, sliders, graphs, and indicators to allow full user interaction. It also provides feedback about the system's status.

What are the software components of the PLC?

The PLCs’ software components are a special group of software that work together to allow the monitoring, design, and execution of PLC programs that control and automate machinery and industrial processes.1- Operating System (OS).

PLC doesn’t use the traditional OS used in smartphones or personal computers. The PLC’s OS is a specially designed real-time software platform used to manage the program execution, system component, and memory allocation for maximizing control and automating industrial processes.This OS provides the necessary infrastructure for running PLC control programs, managing I/O communication, and ensuring real-time performance. It also coordinates the communication between the PLC’s hardware components and handles interrupts to ensure the PLC’s reliable operation.

2- Programming Software.

Programming Environment or software is a software tool used to design, modify, edit, and debug the industrial processes’ control logic and programming instructions through a user-friendly interface using a special programming language such as ladder diagram logic, function block diagrams, and structured text editors.3- Human-Machine Interface (HMI).

The HMI software enables the operators to interact with the PLC system, monitor system parameters, make modifications, and change setpoints and targets of the processes. HMI software offers a graphical interface for displaying, reporting, and alarm handling to optimize industrial processes.How does the PLC system work?

A PLC system executes a specific control program designed for a certain process and written by a programmer to automate and control this process or machinery. The basic operation of a PLC system is as follows:1- Input Signal Detection.

The input signals from field sensors, switches, and input devices are collected and received through the input modules.

2- Program Execution.

Based on the input signals and according to the control program written by the programmer, the PLC system executes these logic instructions that are built to control the behavior of the process.

It also processes and calculates the results according to the programmed logic and makes decisions based on the input data. The PLC generates output signals resulting from the control program and based on the process inputs.

3- Output signal generation.

The output signals are delivered to the external devices like actuators, motors, and valves through output modules. These external devices perform various actions to control industrial processes.

4- Updating inputs and outputs.

The PLC system continuously updates the input signals, program execution, and output signals to re-execute the program with the input updated values and calculate the new output signal.

5- Real-time feedback and monitoring.

enable the system to follow up, monitor, and detect any errors, faults, or deviations from the programmed logic.

What are the programming languages used in PLC?

there are many programming languages used in the design of the PLC programs. The most common program languages are:- Ladder Logic:

- Function Block Diagrams (FBD):

- Instruction List (IL):

- Structured Text (ST):

- Sequential Function Chart (SFC):

Conclusion.

The programmable logic control (PLC) system’s hardware and software make the PLC one of the most used, efficient, and accurate systems in industrial automation to monitor and control machinery and processes especially when working together.The hardware of PLC combines a power supply (PS), CPU, I/Os, communication modules, and programming interface while the software components consist of an Operating System (OS). Programming Software, and Human-Machine Interface (HMI):