Calculate and design your own solar power system

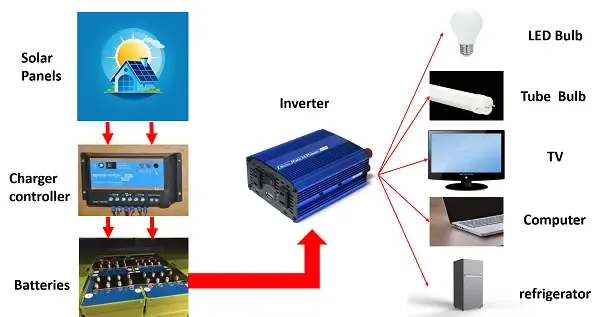

In previous articles, we discussed solar energy and solar power systems as a renewable energy system generating electricity from sunlight in areas that are reached by solar irradiance and are not covered by the national grid's electricity. It is also used to save money from monthly electricity bills and to improve environmental conditions by reducing carbon emissions.Step 1: determination of load calculations

We will make our load calculations based on the most electric sample devices that could exist in our houses. If you need to add more loads, the calculation methods will not be affected. The only change will be in the way of connecting the solar panels and batteries, which will be explained in the article sections on the solar panels and the battery size.Loads:

- 10 lighting LED bulbs with 10 W each.

- 2 tube bulbs with 36 W for each.

- 4 tube bulbs with 18 W for each.

- 1 refrigerator with 160 W.

- 1 computer with 100 W.

- 1 TV with 100 W.

|

Load Name |

Load power (W) |

No of devices |

power (W) |

Operating hours (H/Day) |

Energy (WH/Day) |

|

LED bulbs |

10 |

10 |

100 |

6 |

600 |

|

tube bulbs |

36 |

2 |

72 |

6 |

432 |

|

tube bulbs |

18 |

4 |

72 |

6 |

432 |

|

refrigerator |

160 |

1 |

160 |

8 |

1280 |

|

computer |

100 |

1 |

100 |

6 |

600 |

|

TV |

100 |

1 |

100 |

8 |

800 |

|

Total Power |

604 |

Total Energy |

4144 |

||

- Total power = 604 watts.

- Total energy = 4144 Wh/Day.

- Considering the energy losses in system components (like inverter, batteries, charger controller, and cables), we will add 30% to the total energy losses. So, the new total calculated energy will be updated as follows:

- Total energy = 4144 * 1.3 = 5,387.2 Wh/Day after adding the power losses.

Step 2: Solar panel sizing and calculations.

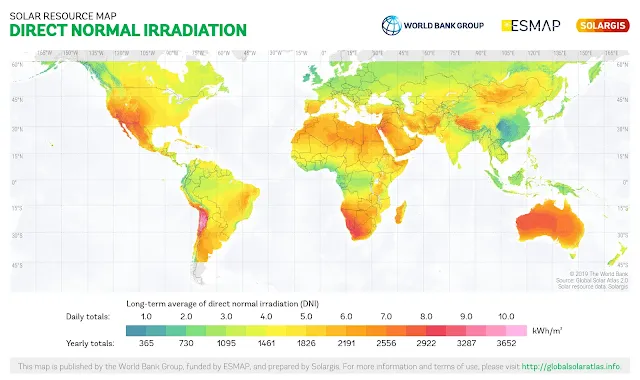

We have to determine the number of hours that we will get power from solar panels during the day. We can get that data from any website that submits such data, like the Global Solar Atlas for example. We determine the location where we want to know the number of hours. Our calculation will be based on 5.5 hours/day. We will determine the power (watts) needed from solar panels to power the loads during the day (for 5.5 hours of the day).

- Total power needed = total energy needed / daily hours = 5387.2 / 5.5 = 979.49 watts We will consider the total needed power from PV solar panels = 1000 watts.

- Based on the common, widely used solar panels in any local market. You can choose the available and suitable solar panels that could be used in your area. Here, we will use any panel with 250 watts as power, 42.8 volts at maximum power point V(MPP), and 6.20 A as short circuit current I(S.C).

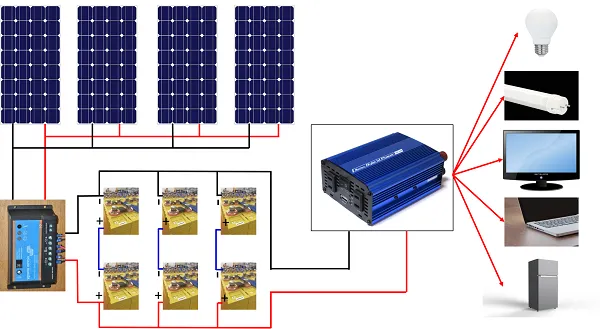

- The number of solar panels needed = 1000 watts / 250 watts = 4 panels.

- Because the panel voltage works with 24 V, the solar panel connections are in parallel.

Step 3: Batteries sizing and calculations.

- Before starting the battery calculation, we should select the system voltage that will be used in all equipment’s design and will be referenced in the connection of batteries and solar panels. We will work with a 24-volt system voltage.

- We determine the current required Ah/day from batteries at 24 system volts.

- Battery capacity = 5387.2 / 24 = 224.46 Ah/day. At 24 system volts.

- These calculations are to operate our load for one day.

- Considering the worst-case calculation for bad weather or days without sunlight, we are making our calculation for 2 days without sunlight. Note that if you have bad weather or days without daylight for more than 2 days, you should increase the number of batteries accordingly.

- Battery capacity for weather worst case = 224.46 * 2 = 448.92 Ah/day. At 24 system volts.

- Considering the depth of discharge or the minimum value of the state of charging (minimum SOC%) could be reached. We will consider that I can take 80 % of the battery charge, noting that the use of full battery charge will affect the battery lifetime. So, the capacity of the batteries will be as follows:

- Battery capacity at 80 % DOD = 448.92 / 0.80 = 561.15 Ah/day.

- Another parameter that should be considered for battery selection is the temperature effect on battery performance. From the datasheet of the battery and from the battery curve we determine the percentage of the used capacity of the battery based on the installed area temperature as the battery performance decreased with the decrease of the temperature. We will consider an 80 % capacity.

- Battery capacity considering site temperature = 561.15 / 0.80 = 701.4375 Ah/day.

- We will use batteries with the following specs: solar battery, 12 volts, 135 Ah. Same as you are free to choose any available batteries in the local market but it should cover the required specs. It will affect the number of batteries based on the battery size and the connection of batteries to get the system's voltage.

- Number of batteries = 701.4375 / 135 = 5.195 (approximately 6 batteries).

- The battery connection will be 3 parallel branches of 2 batteries connected in series.

Step 4: Battery charger controller calculation.

- As the charger controller controls the battery charging from the solar panels, the charging controller will be based on the solar panels' short circuit current I(S.C) and the number of solar panels. Note that we add 20 % as a safety factor for the charger controller.

- Need charge controller’s current = 6.2 * 4 * 1.2 = 29.76 A.

- Depending on the standard charger controller capacity,y we will choose the nearest higher one, which is 30 amps in that case.

Step 5: Inverter calculation.

- The Inverter selection and calculation will be based on the total load power, which in the hour case equals 604 W.

- Note that we will add a safety factor of about 30 % to the sizing of the inverter.

- Inverter power = 604 * 1.3 = 785.2 watts.

- The chosen inverter will be the available nearest higher one (we will consider it 800 watts).

- Now we made our design and all the needed equipment for building our home solar power system manually based on an estimated load and the most commonly used components available in the local market. If there are any changes, the calculation will not be changed. The following are the equipment specs:

|

Solar Panels |

|

|

Power |

250 watts |

|

No of cells |

72 cells |

|

V mpp |

24 volts |

|

I (S.C) |

6.2 amps |

|

Batteries |

|

|

Battery volts |

12 volts |

|

capacity |

135 Ah |

|

DOD |

80% |

|

capacity at normal. Temp. |

80% |

|

Charge controller |

|

|

Battery volts |

24 volts |

|

rated charge current |

30 Amps |

|

Inverter |

|

|

Input voltage |

24 DC voltage |

|

Output voltage |

220 AC voltage |

|

Power |

800 watts |