Introduction to burners

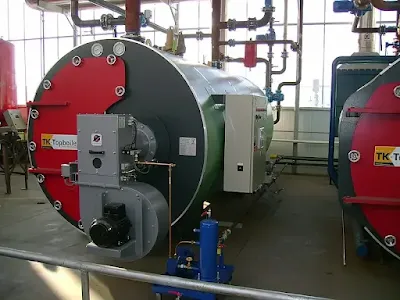

Burners are critical equipment used in heating systems to increase temperature used for heating up and steam generation. It supports many activities like industrial commercial and residential applications. It ensures the warmth of homes and offices and protects people during cold weather and freezing.It is also used in transportation and secures very high temperatures in melting processes for industrial applications like steel, aluminum, and cement manufacturing. It is used in boilers for steam generation which is needed for turbines to generate electricity.

The burner system includes sensors, instrumentations, and control equipment used in the parameters measuring of the burner system like temperature and pressure. The control equipment is to support reaching the maximum performance of the burner. Safety equipment and safety procedures are very essential in all burner systems.

|

| Burner Equipment |

What is the burner?

From a technical perspective, burners are equipment used to mix fuel with air in precise ratios, ignite the mixture, and sustain controlled combustion to generate heat. The primary purpose of a burner is to provide a stable, efficient flame that can be used for heating in a wide range of applications, from residential boilers and furnaces to large industrial processes.What are the advantages of burners?

- High Efficiency and fuel saving.

- Low emissions and carbon footprint reduction.

- Lower operating costs and maintenance costs reduction.

- Precise control of temperature and air-fuel ratio adjustment.

- Small to large scale and retrofit

- Customizable designs and compatibility with automation systems.

- Multiple Fuel Types and a wide range of applications.

- Integrated Safety Controls and Automated Ignition

What are the disadvantages of burners?

- Environmental regulations, especially on NOx and SOx emissions,

- Fuel dependency and cost.

- Emission control costs.

- High temperatures.

- Incomplete combustion

- Greenhouse gas and air Pollution.

- High installation costs:

- Limited renewable options

- Heat loss

- Regular maintenance needed

- Fire and explosion risk

- Operational noise and vibration

What are the residential applications that use burners?

- Water heating.

- Oven and stoves.

- Boilers.

- Barbecue grills.

- Furnaces for cooking and baking.

- Fireplaces in homes and offices.

What are the industrial applications that use burners?

- Large-scale burners are used in furnaces for metalworking, glass production, and ceramics, where high temperatures are required.

- Boilers (for electricity Generation)

- Kilns in cement plants.

- Ovens and Roasters in Food Processing.

- Industrial Furnaces for melting process in ceramic and glass applications

- Petrochemical and Refineries Plants.

- Steam Generators

- Dryers (Industrial).

- Fabric drying in Textile Manufacturing

- Converting waste to ash by Incinerators

- Chemical and Pharmaceutical Plants

What does the Burner system consist of?

As burners are defined as devices designed to facilitate the mixing and controlling of fuel and air to generate heat, they consist of several key components, each playing its role in combustion, ignition, and control of the process. These key components are:1- Fuel System.

Fuel is the main and important part of the burning process. Depending on the fuel type used in the combustion process, there are suppliers for each. For example, pumps are used for oil, solar, and other liquid materials. Pipelines and nozzles are used with the other pressurized sources.What are the types of fuels used in burners?

- Heavy or light Oil Burners are used with heavy oil fuel and light fuel oils, such as kerosene or diesel, It Includes an oil pump, atomizer, and nozzle. In the oil burner, the oil should be heated and pressurized before entering the burner.

- Gas Burners are used with natural, propane, and LPG gas. Normally it is transported through pipelines. Gas burners are widely used in residential heating systems, industrial processes, and electricity generation.

- Solid Fuel Burners are used with Coal and Biomass. It enables the feeding of wood chips, coal, and biomass. These systems use weighing feeders and hoppers control to supply and control the combustion process.

- Dual-fuel burners are designed to use more than one fuel. It can switch between the different types of fuels gas, oil, diesel, and coal. Depending on the burner’s type, these burners can work by mixing different types of fuels.

2- Combustion air System.

The combustion air system is used to supply the process with the fresh air containing oxygen needed for the combustion process. Normally blowers and fans are the key equipment used for this task. The system ensures the right quality and quantity of the supplied air.What are the types of Combustion Air?

- Primary Air is the air that is mixed with the fuel before it enters the combustion zone. It manages the flame characteristics.

- Secondary Air is the added air after the primary air-fuel mixture is ignited. It supports the completion of the combustion process by adding oxygen to the flame.

- Tertiary Air is used in advanced burner designs in industrial furnaces and kilns. It is introduced further downstream to control temperature distribution and flame shape.

What are the advantages of a good Combustion Air System?

- Improved Combustion Efficiency by Ensuring a complete combustion with minimal fuel.

- Reduces the pollution and achieves the environmental targets.

- Optimize the Burner Performance at different operation parameters.

- Energy Savings by reducing fuel consumption and energy utilization.

3- Ignition System

The ignition system’s function is to trigger the combustion process by initiating a spark. This ignition system ensures the efficient and safest operation of the burner. It could be a Pilot Burner, Spark Ignitor, or Hot Surface Ignitors (HSI)where a resistive element that heats up to a high temperature ignites the fuel-air mixture.4- Compressed air system.

A compressed air system in burners plays a crucial role in combustion efficiency, especially in industrial burners where:- It is used for atomizing the fuel to improve the overall burner’s performance.

- It supplies the exact air-fuel ratio for good combustion

- Compressed air is used to cool down the burners’ heads from overheating.

- Compressed air support in the ignition phase at the burner’s start.

- Compressed air stables the burner’s flame shape and turbulence.

5- Burners’ safety precautions

Safety precautions are the concerns that should be considered in the burner’s operation to ensure the safety of equipment and people.- Avoiding gas and oil leakage.

- Flame supervision should be used.

- Proper ventilation and combustion air supply to avoid hazards of incomplete combustion.

- Overheating can cause damage to the equipment, and increase the risk of fires.

- The ignition system of burners should be regularly inspected to ensure safe operation.

- Proper pressure control is important to prevent overpressure situations.

- Clear and well-defined shutdown procedures ensure that burners can be safely turned off.

No comments:

Post a Comment